In the manufacturing industry, growth is not driven by machines alone. It is driven by clarity, discipline, and the ability to manage people through data rather than assumptions. Many manufacturers invest heavily in equipment, automation, and SOPs, yet still struggle with inconsistent execution, unclear priorities, and reactive management. This is where a Performance Management System becomes a critical business foundation.

The long-term experience of HUA HUAT MANUFACTURING SDN. BHD., widely recognised through its consumer brand BIKA Food (https://www.bika.com.my/), offers a powerful real-world example of how a Performance Management System can transform operational clarity, employee focus, and data-driven decision-making in a manufacturing environment.

In a testimonial shared by Eryn, the Chief Operating Officer (COO) of BIKA Food, she explains how the company has been using the sandmerit Performance Management System for several years—and why it continues to deliver value well beyond initial implementation.

Manufacturing Without Clarity Is Expensive

Manufacturing organisations often face a hidden cost: lack of clarity.

Before implementing a structured Performance Management System, many companies rely heavily on SOPs, verbal instructions, and supervisor intervention to guide daily work. While SOPs are essential, they do not always answer the most important daily questions employees face:

- What should I focus on today?

- Which task has the highest priority?

- How do I know if I am performing well?

According to Eryn, this was a common challenge in the past. Employees frequently had to refer back to SOPs or ask which tasks should take priority. This created delays, uncertainty, and inefficiencies—especially as the organisation grew.

The introduction of the sandmerit Performance Management System changed this dynamic fundamentally.

Clear Goals Create Clear Execution

One of the most important benefits highlighted by Eryn was clear understanding of goals across the organisation.

Since implementing the Performance Management System, everyone at BIKA Food knows:

- What they are responsible for

- What outcomes are expected

- How their performance is measured

This level of clarity removes guesswork from daily operations. Employees no longer wait for instructions or second-guess priorities. Instead, they arrive at work with a clear objective for the day.

In manufacturing, this clarity directly impacts:

- Productivity

- Quality consistency

- Speed of execution

When expectations are clear, performance becomes repeatable rather than dependent on individual interpretation.

From Task-Based Work to Purposeful Work

Another key transformation described in the testimonial is the shift from task-based work to purpose-driven work.

Eryn explained that employees now come to work with a specific objective each day. This is a subtle but powerful change. Rather than simply completing tasks, employees understand:

- Why the task matters

- How it contributes to department goals

- How it supports the company’s long-term direction

A Performance Management System that connects daily activities to measurable objectives creates ownership. Employees begin to manage themselves because they understand what success looks like.

This is especially important in manufacturing, where supervisors cannot constantly monitor every detail. Purposeful work reduces dependency on supervision and increases consistency.

Reducing SOP Dependency Through Performance Priorities

Interestingly, the clarity created by the Performance Management System reduced over-reliance on SOPs.

Eryn noted that employees no longer needed to constantly check SOPs or ask which task should be prioritised. With clear KPIs in place, employees understood:

- Which activities had the greatest impact

- What to focus on first

- How to balance speed, quality, and efficiency

This does not replace SOPs. Instead, the Performance Management System works alongside SOPs by providing priority and direction.

In manufacturing, where time and accuracy are critical, this combination significantly improves operational flow.

The Core Power of Measurement in a Performance Management System

One of the strongest messages from Eryn’s testimonial was the importance of measurability.

She emphasised that the true value of the sandmerit Performance Management System lies in its ability to make performance measurable. This reflects a fundamental management principle:

If you cannot measure it, you cannot manage it.

Before KPIs are clearly defined, management often relies on intuition, experience, or delayed reports. This leads to reactive decision-making and inconsistent performance control.

With a structured Performance Management System, BIKA Food was able to:

- Convert expectations into measurable indicators

- Track performance objectively

- Replace assumptions with data

Measurement brings clarity not only to management, but also to employees.

Managing Through Data, Not Guesswork

Eryn made a very clear statement: once things are measurable, they can be managed effectively. Without measurement, management becomes impossible.

This is especially true in manufacturing, where small inefficiencies can compound into major losses over time.

With the Performance Management System in place, BIKA Food’s management team could:

- Monitor progress in real time

- Identify gaps early

- Take corrective action based on facts

Instead of reacting to problems after they escalated, management could intervene earlier and more accurately.

This shift from guesswork to data-driven management is a key reason why the system continues to be used years after implementation.

Tracking Progress Toward Long-Term Business Goals

Beyond daily execution, the sandmerit Performance Management System also serves as a platform for tracking long-term progress.

Eryn described it as an excellent tool for measuring whether the company is moving closer to its ultimate goals. This is a crucial distinction.

Many organisations measure activity, but few measure strategic progress. A mature Performance Management System bridges this gap by:

- Linking operational KPIs to business objectives

- Showing whether improvements are driving growth

- Providing leadership with a clear performance overview

For a well-known snack brand like BIKA Food, this visibility supports better planning, stronger execution, and sustainable competitiveness.

Long-Term Adoption Proves Real Value

One of the most convincing aspects of BIKA Food’s story is longevity. The company has been using the sandmerit Performance Management System for several years—not as a short-term initiative, but as a core management framework.

This long-term adoption demonstrates:

- Trust in the system

- Consistent value over time

- Alignment with the company’s growth strategy

In manufacturing, where continuous improvement is essential, a Performance Management System must deliver sustained benefits—not quick wins that fade after implementation.

Why a Performance Management System Is a Strategic Asset in Manufacturing

BIKA Food’s experience illustrates how a Performance Management System can become a strategic asset rather than an administrative burden.

Through clarity, measurability, and data-driven management, the company achieved:

- Stronger execution discipline

- Reduced confusion and rework

- Better alignment between people and goals

For manufacturers operating in competitive markets, this level of operational control and clarity is a significant advantage.

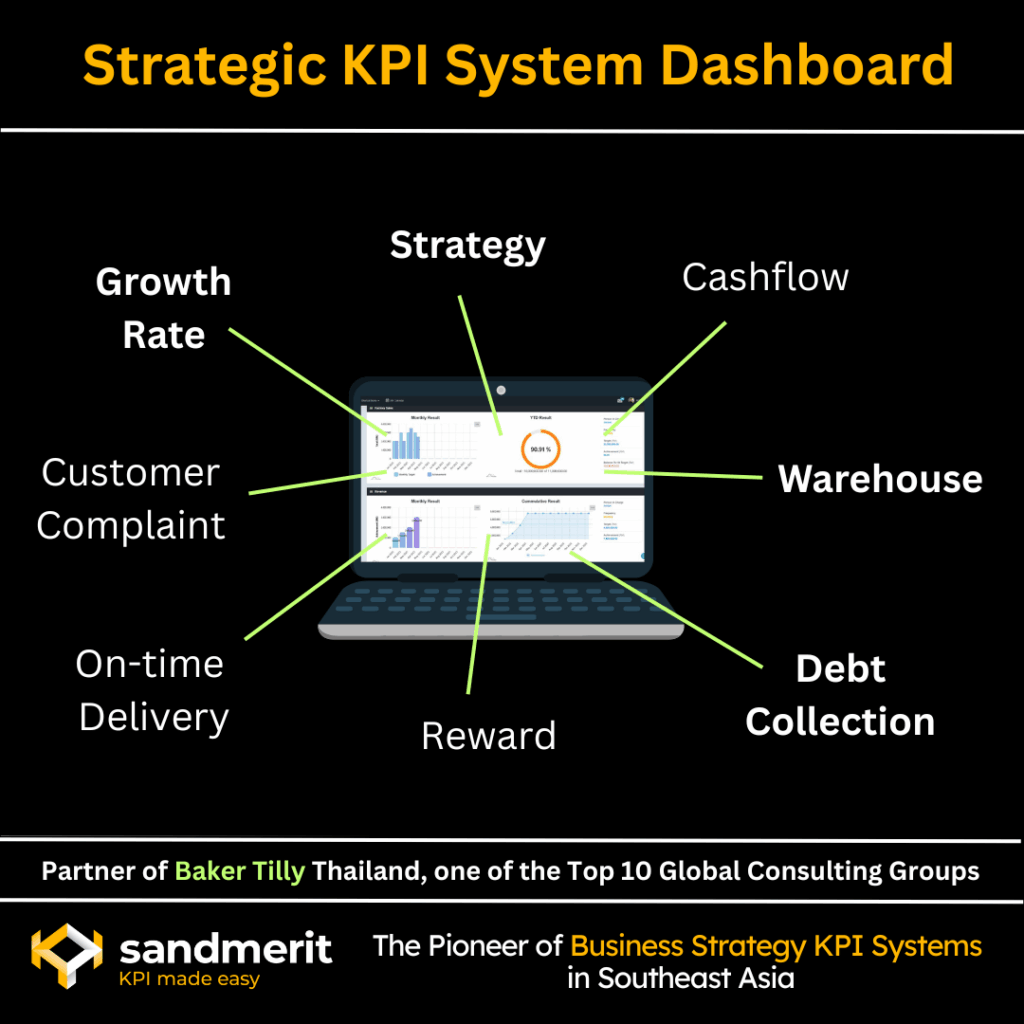

Why sandmerit Works for Manufacturing Companies

What differentiates sandmerit is that its Performance Management System is not just software. It is a structured methodology that:

- Clarifies expectations

- Aligns daily work with strategy

- Enables measurable accountability

- Supports long-term improvement

For BIKA Food, this approach created consistency across teams and sustained performance improvement over many years.

Final Reflection: Performance Management Is About Direction and Discipline

The BIKA Food journey reinforces a critical lesson for manufacturers:

performance management is not about controlling people—it is about giving them direction and discipline through clarity and data.

When employees know what to do, why it matters, and how success is measured, execution becomes consistent and scalable.

A well-implemented Performance Management System empowers people, strengthens management, and supports sustainable growth in manufacturing organisations.

Watch the full testimonial video here:

https://www.youtube.com/watch?v=MPEem89MOdY

#PerformanceManagementSystem #ManufacturingIndustry #KPISystem #DataDrivenManagement #OperationalExcellence #ContinuousImprovement #EmployeeClarity #ManufacturingLeadership #BIKAFood #HuaHuatManufacturing #JohorBahru #sandmerit #WilsonTen #KPIKing