Manufacturing is one of the most demanding industries when it comes to execution discipline. Machines can be upgraded, processes can be improved, but without a structured performance management system, even the best factories struggle to sustain productivity, quality, and profitability over time.

Many manufacturing companies still rely on experience, manual tracking, and fragmented Excel files to manage performance. While this may work temporarily, it becomes a serious limitation as operations scale, product complexity increases, and workforce expectations change.

This is where a well-designed performance management system becomes a strategic necessity rather than an operational option.

Manufacturing Challenges Go Beyond Production Output

Modern manufacturing leaders face challenges that extend far beyond production numbers. They must manage skill gaps, quality consistency, cost control, compliance, and employee engagement—often across multiple departments and locations.

Without a structured performance management system, these challenges are addressed reactively. Problems are discovered late, training is unplanned, and improvement initiatives lack clear measurement. Over time, this leads to inefficiency, frustration, and declining competitiveness.

A performance management system changes this dynamic by creating visibility and alignment across the entire organisation.

Turning KPIs into a Workforce Capability Tool

One of the most misunderstood aspects of KPIs in manufacturing is their role in workforce development. KPIs are not only about measuring results; they are about identifying capability gaps.

When KPIs are clearly defined and tracked, management can immediately see:

- Where performance is falling short

- Which skills are missing

- What type of training or tools are required

This allows manufacturing companies to plan employee development strategically rather than relying on assumptions. Instead of sending staff for generic training, leaders can invest in targeted capability building that directly impacts production efficiency and quality outcomes.

Simplifying Manufacturing Strategy Execution

Manufacturing strategy often fails not because it is poorly designed, but because it is poorly executed. Vision statements and strategic goals remain at management level, disconnected from daily operations.

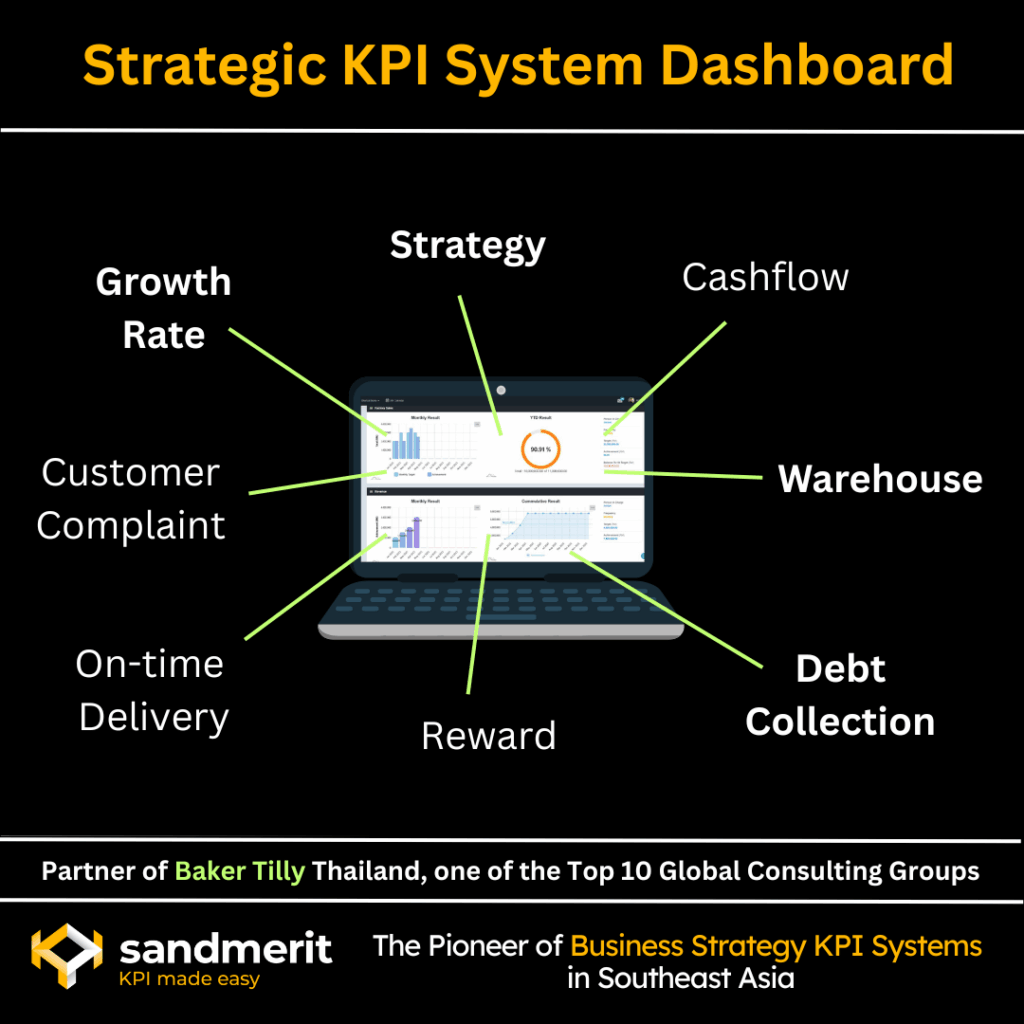

A performance management system bridges this gap by translating strategy into measurable KPIs at every level—company, department, and individual.

When employees understand how their daily tasks affect cost, quality, delivery, and profitability, execution becomes purposeful. Strategy stops being abstract and becomes actionable.

Quarterly tracking of critical indicators such as profit, revenue, margins, rejection rates, and efficiency enables leadership to identify issues early and intervene before they escalate into major losses.

Driving Consistency in Productivity, Quality, and Efficiency

In manufacturing, improvement must be consistent. A one-time productivity boost is meaningless if quality declines or costs increase.

A structured performance management system ensures balance. Productivity targets are aligned with quality KPIs and efficiency metrics, preventing short-term gains that damage long-term performance.

Employees gain clarity on expectations, supervisors manage using data instead of emotion, and management decisions become fact-based rather than reactive.

This consistency is what separates high-performing manufacturing organisations from those that constantly struggle with firefighting.

Beyond Operations: Supporting Functions Matter Too

Many factories focus performance tracking only on production. However, supporting functions such as planning, quality assurance, finance, HR, and administration play a critical role in manufacturing success.

A holistic performance management system ensures that these supporting roles are also aligned with operational goals. Planning accuracy improves, cost control strengthens, and decision-making becomes faster and more reliable.

Manufacturing performance is a system-wide outcome—not a production-only responsibility.

Moving Away from Manual KPI Tracking

Excel-based KPI tracking has long been the default in manufacturing. However, manual systems are prone to delays, errors, version control issues, and limited transparency.

A modern performance management system automates data consolidation, provides real-time visibility, and enables structured performance reviews. This frees managers from administrative work and allows them to focus on leadership and improvement.

For manufacturing companies aiming to digitalise operations, replacing manual KPI tracking is one of the most impactful steps they can take.

Integrating Performance with Rewards and Feedback

Performance management only works when employees believe it is fair. A comprehensive performance management system links KPIs with reward mechanisms such as merit appraisal and performance-based incentives.

When employees understand how their performance affects rewards, motivation increases. When 360-degree feedback is integrated, development becomes more balanced and objective.

This creates a performance culture where accountability and fairness coexist—an essential foundation for long-term manufacturing stability.

Building Manufacturing Resilience Through Systems

Resilient manufacturing companies are not those without problems, but those with systems that allow them to respond quickly and improve continuously.

A performance management system provides that resilience. It enables leaders to:

- Detect issues early

- Develop people strategically

- Maintain execution discipline

- Sustain improvement over time

In an industry where margins are tight and competition is intense, this discipline is a decisive advantage.

A Clear Direction for Manufacturing Leaders

For manufacturing leaders planning long-term growth, the question is no longer whether to implement a performance management system—but how soon.

Those who invest early build stronger teams, clearer strategies, and more predictable results. Those who delay often find themselves reacting to problems rather than leading improvement.

In manufacturing, systems do not replace leadership—but they amplify it.

URL: https://youtu.be/htWe-UC4xgA

#PerformanceManagementSystem #ManufacturingIndustry #ManufacturingKPI #OperationalExcellence #ProductivityImprovement #QualityManagement #ManufacturingEfficiency #WorkforceDevelopment #StrategicExecution #DataDrivenManagement #HRTech #DigitalManufacturing #sandmerit #WilsonTen #KPIDaren